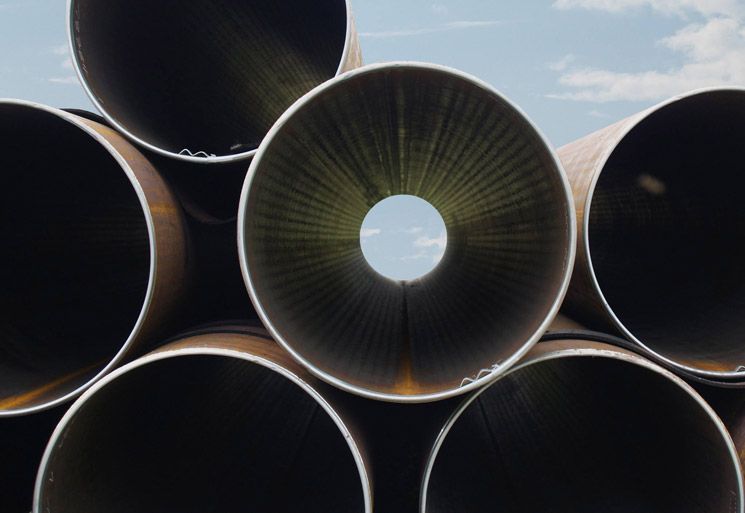

LSAW (Longitudinal double submerge arc welding) carbon steel pipe is a type of SAW pipe made of steel plates that were hot rolled by JCOE, UOE, or COE forming technology. It can be used for a wide range of applications, such as petroleum and chemical production, oil and gas transportation, heavy machinery manufacturing, and construction.

LSAW Pipe Specifications

Our LSAW pipes are produced using the Longitudinally Submerged Arc Welding procedure, ensuring a strong and durable product. These pipes are available in various dimensions and steel grades, each meeting rigorous production standards. The surface coatings applied enhance their durability and resistance to corrosion. The end types and joint methods can be customized to meet specific application requirements. These pipes are machined to perfection and find extensive applications in industries like oil and gas, and water supply.

| Procedure | LSAW (Longitudinally Submerged Arc Welding) |

| Dimensions | 219.1mm ~1626mm |

| 8″ ~ 64″ | |

| DN200~ DN1600 | |

| Thickness | 6mm ~75mm |

| Unit Length | 3 ~ 18 mtrs |

| Standards | API 5L |

| EN10025 | |

| DIN17100 | |

| JIS G3101 | |

| ASTM A252 | |

| AWWA C200-97 | |

| Surface Coating | Varnishing, Oiling, Hot Dip Galvanizing |

| FBE, 2PP, 3PP, 2PE, 3PE | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Coupling, Clamp, Pipe Shoulder, Welding |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

| Application | Oil & Gas, Water Transmission, Solar Energy, Fire Fighting, Construction, Piling Work, Mechanical Engineering, Fabrication |

What is LSAW Pipe?

LSAW (Longitudinal Double Submerged Arc Welding) carbon steel pipe welds steel plates that have been hot rolled using JCOE, UOE, or COE forming process.

LSAW (Longitudinal double submerge arc welding) is a circular arc method used to weld carbon and low alloy steels at low hydrogen concentrations. It differs from the more conventional single or differential-current SAW processes in that it employs both an AC frequency current and a high voltage direct current electrode. A DC electrode guarantees that the arc vortex forms a completely closed circuit and avoids any contact with the metal base material, allowing for far more control over penetration levels and weld quality.

Where Are LSAW Pipes Used?

LSAW pipe has found widespread use in the oil and gas pipelines, which require pipes with particularly large diameters, thick wall thicknesses, and high strengths in order to efficiently transport hydrocarbons over great distances. In the meanwhile, LSAW pipe comes highly recommended for a variety of applications including weight bearing piles, combination wall piles, water treatment, the thermal sector, bridge construction, and others.

Oil & Gas

Construction

Water Transmission

Piling Work

Mechanical Engineering

Steel Fabrication

How Is LSAW Pipe Made In The UOE Method?

The term UOE is the abbreviation for U-O-E, which is a method used for the production of longitudinally welded large diameter pipes. The production process of UOE pipes is divided into three steps: pre-bending, forming, and longitudinal welding. First, the plate is pre-bent by different radii by a variety of forming presses. After that, it will be deformed into U-shape and O-shape by a specific forming press. Finally, these two pre-shaped plates are welded together in an LSAW process to form a final tube with satisfactory wall thicknesses.

Where Are LSAW Pipes Used?

LSAW pipe has found widespread use in the oil and gas pipelines, which require pipes with particularly large diameters, thick wall thicknesses, and high strengths in order to efficiently transport hydrocarbons over great distances. In the meanwhile, LSAW pipe comes highly recommended for a variety of applications including weight bearing piles, combination wall piles, water treatment, the thermal sector, bridge construction, and others.

Oil & Gas

Construction

Water Transmission

Piling Work

Mechanical Engineering

Steel Fabrication

How Is LSAW Pipe Made In The UOE Method?

The term UOE is the abbreviation for U-O-E, which is a method used for the production of longitudinally welded large diameter pipes. The production process of UOE pipes is divided into three steps: pre-bending, forming, and longitudinal welding. First, the plate is pre-bent by different radii by a variety of forming presses. After that, it will be deformed into U-shape and O-shape by a specific forming press. Finally, these two pre-shaped plates are welded together in an LSAW process to form a final tube with satisfactory wall thicknesses.

How Is LSAW Pipe Made In The COE Method?

In the Electric Resistance Welding process, ERW pipe is made by shaping a flat sheet of steel into a cylindrical shape first. A current is passed between the steel cylinder’s two edges to heat the steel to the point where the edges are pressed together with no welding material required.

What Is The Difference Between LSAW Pipe And SSAW Pipe?

LSAW and SSAW are SAW (submerged arc welded) pipe variations. The distinction between them is the technique in which they are welded. In LSAW pipes, the welding is longitudinal, meaning that steel (hot-rolled coil plate) is rolled into a pipe and the seam is longitudinally welded. In SSAW, steel coils are spirally welded, like a helix, such that the coil (strip) adopts the shape of a pipe. SAW pipes are mostly used for transporting oil and gas.

LSAW Pipe

- Relatively Expensive In Price

- Welding Direction: Longitudinal Direction

- Production Efficiency:Low Efficiency

- Outer Diameter: 16 Inch To 60 Inch

- Main Application: Medium/High Pressure

- Thickness Tolerance: Relatively Accurate

- Geometry Accuracy: High

SSAW Pipe

- Low Cost

- Welding Direction: Spiral Direction

- Production Efficiency:High Efficiency

- Outer Diameter: 20 Inch To 100 Inch

- Main Application: Construction

- Thickness Tolerance: Relatively Accurate

- Geometry Accuracy: Low