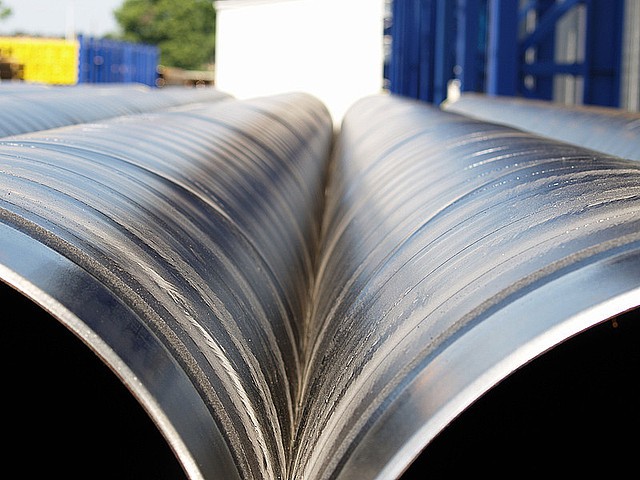

SSAW pipes are often utilized for diameters greater than 20 inches NPS (Outside Diameter). The spiral welded pipe has a circular cross-section and is formed using double wire-double-sided submerged arc welding, an ae/a technique. This material has excellent strength, low porosity, and low permeability, making it suitable for oil and natural gas. The hydrostatic test, tensile strength, and cold bending performance of the weld joint must conform to the specifications for the SSAW pipe.

SSAW Pipe Specifications

Our SSAW pipes are produced using the Spiral Submerged Arc Welding procedure, ensuring high strength and durability. Available in various dimensions and steel grades, these pipes meet stringent production standards. The surface coatings applied provide additional protection against environmental factors. We offer different end types and joint methods, all machined to precision. SSAW pipes are commonly used in applications like water supply, construction, and oil and gas industries.

| Procedure | SSAW (Spiral Submerged Arc Welding) |

| Dimensions | 219.1mm ~ 2032mm |

| 8″ ~ 80″ | |

| DN200~ DN2000 | |

| Thickness | 6mm ~ 25.4mm |

| SCH 20~SCH XXS | |

| Unit Length | 3 ~ 18 mtrs |

| Standards | API 5L |

| ASTM A53 | |

| EN 10217 | |

| EN 10219 | |

| ASTM A500 | |

| Surface Coating | Varnishing, Oiling, Hot Dip Galvanizing |

| FBE, 2PP, 3PP, 2PE, 3PE | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Coupling, Clamp, Pipe Shoulder, Welding |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

| Application | Oil & Gas, Water Transmission, Solar Energy, Fire Fighting, Construction, Piling Work, Mechanical Engineering, Fabrication |

What is SSAW Pipe?

The production of SSAW pipe is a continuous operation. After the steel coil is unwound, it is flattened and shaped by angled rollers into a cylinder of the necessary diameter. Two spirals are joined by an interior and exterior weld seam to produce the pipe. A cross-seam is created by butt-welding a new coil to the trailing edge of the pipe at the end of the coil. The pipe is cut to length and, if necessary, its ends are beveled before being examined for quality control.

The size range for SSAW pipe is 24 inches to 144 inches, and it is generally used for water distribution service due to its resistance to corrosion and ability to handle high pressures and temperatures in the presence of hostile media such as brines or other chemicals.

What is SSAW Pipes Used for?

Due to the fact that SSAW pipe can withstand a significant amount of pressure, it is utilized in a wide variety of construction applications. Piling, structural applications, water pipelines, slurry pipelines, dredge pipelines, and other types of pipelines are some of the uses for SSAW pipe.

Oil & Gas

Construction

Water Transmission

Piling Work

Steel Fabrication

Mechanical Engineering

What Is SSAW Pipe Manufacturing Process?

The production of SSAW pipes using the spiral welding technique is one of the most efficient and cost-effective methods available. Typically, a helical submerged arc weld is utilized in the production of spiral welded pipe, which is made from steel coil. The configuration of spiral welded pipe mills enables a considerable degree of flexibility, which makes it possible to manufacture a broad variety of pipe sizes and wall thicknesses.

What Is The Difference Between SSAW Pipe And LSAW Pipe?

SSAW Pipe and LSAW Pipe are both SAW (submerged arc welded) pipe types often utilized for oil and gas transportation. The process through which they are welded distinguishes them. Steel coils are spirally welded, like a helix, in SSAW, such that the coil (strip) takes on the shape of a pipe. The welding of LSAW pipes is longitudinal, which means that steel (hot-rolled coil plate) is rolled into a pipe and the seam is longitudinally welded.

SSAW Pipe

- Low Cost

- Welding Direction: Spiral Direction

- Production Efficiency:High Efficiency

- Outer Diameter: 20 Inch To 100 Inch

- Main Application: Construction

- Thickness Tolerance: Relatively Accurate

- Geometry Accuracy: Low

LSAW Pipe

- Relatively Expensive In Price

- Welding Direction: Longitudinal Direction

- Production Efficiency:Low Efficiency

- Outer Diameter: 16 Inch To 60 Inch

- Main Application: Medium/High Pressure

- Thickness Tolerance: Relatively Accurate

- Geometry Accuracy: High